Managing warehouse operations with spreadsheets might have worked in the early stages of your business, but it quickly becomes inefficient as complexity increases. Manual updates, siloed data, and human error make it difficult to respond quickly or scale operations effectively.

Many growing businesses are now adopting modern inventory management software solutions that combine the power of big data with a cloud-based WMS (warehouse management system). These tools not only simplify day-to-day workflows but also support smarter, data-driven decision-making.

Why Spreadsheets Fall Short

Spreadsheets introduce several challenges:

Delayed updates create inaccurate inventory records

Errors during manual entry lead to shipping issues or lost stock

Teams lose time reconciling multiple versions of files

Real-time insights are difficult to obtain

As SKU counts rise or multichannel fulfilment becomes the norm, these issues begin to affect profitability and efficiency.

The Role of Big Data in Inventory Management

Big data inventory management is helping businesses shift from reactive decisions to predictive strategies. Using real-time scan data, IoT sensors, and past sales trends, warehouses can make smarter decisions.

How Big Data Improves Inventory Management

With real-time inventory tracking, barcode scans and transactions are automatically updated, giving full visibility into current stock levels. Predictive analytics supports accurate demand forecasting by factoring in seasonality, sales history, and supplier performance. This helps reduce overstock, minimize holding costs, and keep inventory moving.

WMS vs Spreadsheets for Inventory Management

A warehouse management system software does far more than spreadsheets can. It connects core warehousing functions like picking, packing, returns, labour tracking, and shipping. Through integrations with ecommerce platforms and logistics providers, it creates a connected environment that supports faster and more reliable order fulfilment.

Unlike spreadsheets that provide static data, a WMS offers live dashboards, real-time KPIs, and expiry tracking. Machine compatibility with tools like ASRS or AGVs further streamlines operations.

Benefits of Cloud-Based WMS vs Traditional Systems

Choosing a cloud-based WMS gives you access to real-time data across locations, fast system updates, and minimal infrastructure investment. These platforms are easier to deploy, require less maintenance, and offer the flexibility that legacy systems often lack.

WMS Inventory Optimization in Action

Modern warehouse systems support automation of reorder points using historical data and real-time stock levels. Labour allocation becomes more efficient, and staff performance improves through task prioritization and goal tracking. In industries with strict traceability requirements, such as food and pharmaceuticals, a cloud-based WMS helps identify affected batches instantly during recalls.

What to Look for in Inventory Management Software Solutions

Before selecting a system, consider whether it offers:

Cloud scalability

API and EDI integration

Labour performance tools

IoT and automation compatibility

Expiry and lot control

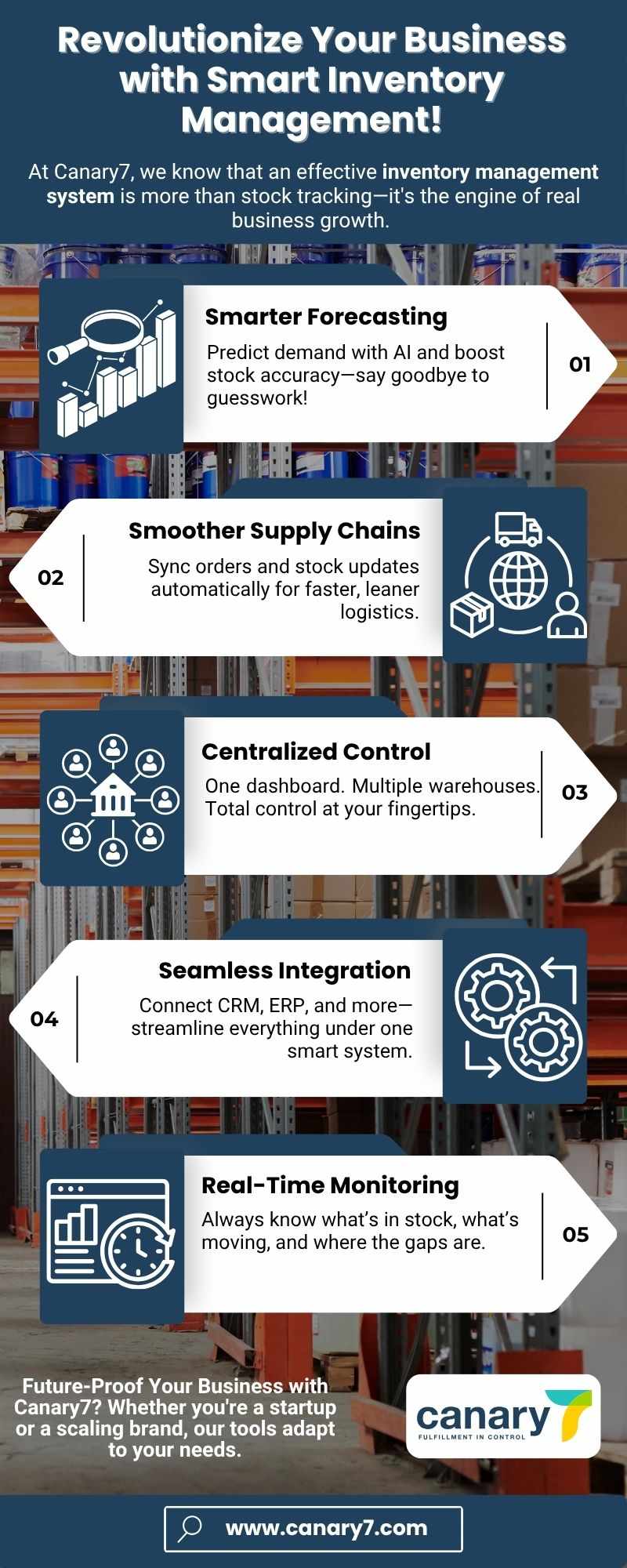

Smarter Warehousing with Canary7 WMS

Canary7 — an advanced warehouse management system software is tailored to meet the demands of fast-moving, high-growth operations. It combines the flexibility of a cloud-based WMS with the intelligence of big data inventory management. From real-time tracking to ecommerce and courier integrations, Canary7 supports more accurate, efficient, and scalable inventory strategies.

Want to make the switch from spreadsheets to a smarter solution? Book a free demo with Canary7 and explore how it can transform your warehouse operations.

Write a comment ...